The technology for modern printing is moving faster than ever. For all printers, whether you are already in business or wish to start one, this makes the choice of UV DTF versus traditional DTF one of the most important decisions you will make. Neither one is weaker than the other, the use of each depends on the desired outcome . Others continue to use the old DTF technique for fabrics. Many others are converting to the newer UV DTF printer because of its speed and capability of printing on hard materials.

If you are uncertain about which one is more suitable for your business, this comparison will offer help. Here’s a breakdown of the main differences between UV DTF and regular DTF – from materials and output to longevity and price.

Printing Surfaces: Fabric vs. Hard Materials

The type of surfaces each one works on is one of the major differences between UV DTF and traditional DTF. Regular DTF is intended to be used with soft materials – mostly fabric. It works best with t-shirts, hoodies, cotton bags, and other clothing related items. For those in the custom apparel or uniform printing, traditional DTF remains superior. It takes washes and wears well, and the color quality is excellent.

Conversely, UV DTF is meant to be much more than for use on fabric. It enables printing onto rigid surfaces such as glass, wood, acrylic, metal, plastic, ceramic, and leather. The possibilities are endless – water bottles, phone cases, jars for candles, and packaging boxes. Your business isn’t limited to clothing with a UV DTF printer. You’re able to get into more product categories and be able to have personalized items that are really unique.

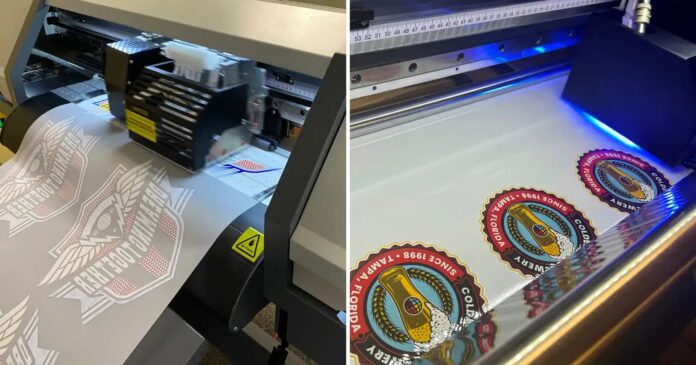

Printing Process: Heat vs. UV Light

Traditional DTF printing has a longer, more detailed process. It starts with printing a design on a special film using DTF inks. Then, hot-melt powder is applied to the printed area. After that, it’s heat-cured before finally being transferred to fabric using a heat press machine. While this method delivers reliable results, it includes several steps that require time, equipment, and precision.

UV DTF, in contrast, uses a simpler and faster process. The design is printed on a film with UV-curable ink. As the ink is printed, it is instantly dried (or cured) using UV light. After printing, the film is peeled and pressed onto the surface—no heat press required. This instant-dry feature makes UV DTF much faster, especially for bulk orders. If your priority is speed and reducing manual steps, UV DTF can drastically improve your daily workflow.

Durability and Quality of Print:

The durability of your printed products matters—not just for customer satisfaction but for your brand reputation too. Traditional DTF prints are long-lasting when applied to fabric. The prints stretch with the material, don’t easily crack, and remain bright after many washes. That’s why clothing brands still prefer this method for mass-producing custom garments.

However, when it comes to hard items, UV DTF clearly wins. The UV-cured inks used in this process are highly durable. They are scratch-resistant, waterproof, and can withstand long-term use without fading. Whether it’s a customized mug or a phone case, the finish feels premium and stays intact over time. This makes UV DTF ideal for businesses that want to offer high-quality, long-life products outside the clothing industry.

Visual Finish and Customer Appeal:

The look and feel of your final product play a huge role in customer experience. Traditional DTF gives a smooth, soft finish on fabric. It feels comfortable to wear and blends naturally with the material. This is ideal for everyday wear like t-shirts, uniforms, and sportswear.

In comparison, UV DTF has a very different visual impact. The prints are slightly raised, giving a textured, high-gloss finish. This effect feels more luxurious and catches the eye—perfect for premium packaging, branded merchandise, or gifts. If you’re targeting high-end customers or want your products to feel more special, UV DTF provides that added value.

Investment, Cost, and Business Growth

Cost is always a deciding factor, especially for startups and small businesses. Traditional DTF printers are generally more affordable. The inks, powder, and PET film are widely available, making it easy to manage operating costs. If you’re just starting out or focusing only on textiles, this is a very practical and low-risk choice.

On the other hand, UV DTF printers do require a higher initial investment. The equipment is more advanced, and UV inks cost more. However, this extra cost is balanced by the variety of products you can offer and the faster turnaround. If you’re planning to grow your product catalog and serve more industries—like gifts, décor, and corporate branding—the investment can pay off quickly. Many successful businesses are now using advanced solutions from providers like DTF LINKO to expand their production with both speed and reliability.

Which One Is Right for You?

Choosing between UV DTF and traditional DTF depends on what kind of products you want to sell, who your customers are, and how fast you want to grow. If your business is centered around fashion, teamwear, or fabric printing, traditional DTF is still an excellent option that offers consistent results.

However, if you want to explore new markets, create high-end products, and increase your profit margins, UV DTF gives you more freedom. You can produce personalized items for weddings, businesses, events, and holidays—all with a fast, clean, and reliable process.

Some smart entrepreneurs are even combining both technologies. They use traditional DTF for clothing and UV DTF for accessories, packaging, and promotional items. This mixed approach helps maximize creativity, revenue, and customer satisfaction.

Final Thoughts

The world of printing is evolving, and so should your business. Both UV DTF and traditional DTF have unique strengths. The key is to match the technology with your business goals. If you want simple, reliable garment printing, traditional DTF is tried and tested. But if you’re ready to take things to the next level—with faster production, wider materials, and high-end results—a UV DTF printer is the smart next step.

No matter which path you choose, focus on quality, consistency, and creativity. Because at the end of the day, great printing isn’t just about machines—it’s about what you create with them.