Introduction

In industries where material durability and resistance to pressure are critical, the Hydraulic Burst Test is a vital evaluation method. This test measures the strength of materials—such as metals, plastics, textiles, and packaging films—by subjecting them to increasing hydraulic pressure until they rupture. A hydraulic bursting strength tester is the specialized equipment used to conduct this test, providing essential data for quality control, research, and compliance with industry standards.

This article explores the principles, applications, and benefits of the Hydraulic Burst Test, along with the working mechanism of a hydraulic bursting strength tester.

What is a Hydraulic Burst Test?

The Hydraulic Burst Test is a destructive testing method that determines the maximum pressure a material can withstand before failing. It is widely used in industries such as:

Packaging (e.g., testing the strength of bottles, containers, and films)

Textiles (e.g., evaluating the burst resistance of fabrics, geotextiles, and protective clothing)

Automotive & Aerospace (e.g., assessing fuel tanks, hoses, and composite materials)

Medical Devices (e.g., testing the durability of IV bags and surgical implants)

The test involves applying controlled hydraulic pressure to a material sample until it bursts, recording the peak pressure (burst strength) at the point of failure.

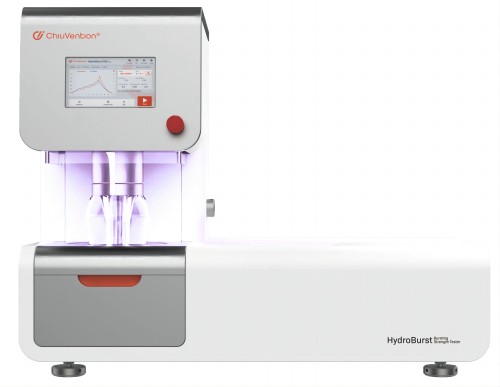

How Does a Hydraulic Bursting Strength Tester Work?

A hydraulic bursting strength tester operates using a hydraulic system to exert uniform pressure on a test specimen. The key components include:

Hydraulic Pump – Generates the required pressure.

Pressure Chamber – Holds the test specimen securely.

Diaphragm or Piston – Transmits hydraulic pressure evenly to the sample.

Pressure Gauge/Sensor – Measures and records the pressure at which the material bursts.

Control Unit – Manages the test parameters and data logging.

Test Procedure:

Sample Preparation – The material sample is clamped securely in the testing chamber.

Pressure Application – Hydraulic fluid is pumped into the chamber, increasing pressure gradually.

Burst Detection – The moment the material ruptures, the peak pressure is recorded.

Data Analysis – The burst strength value is compared against industry standards or product specifications.

Advantages of Using a Hydraulic Bursting Strength Tester

High Accuracy & Repeatability – Hydraulic systems provide precise pressure control, ensuring reliable test results.

Wide Pressure Range – Capable of testing materials from low-strength films to high-pressure industrial components.

Versatility – Suitable for multiple materials, including metals, plastics, rubber, and textiles.

Compliance with Standards – Meets international testing standards such as:

ASTM D3786 (Textile Burst Testing)

ISO 2758 (Paper Burst Strength)

ASTM F2054 (Flexible Packaging Burst Testing)

Automated Testing – Modern testers feature digital controls and software for automated data recording.

Applications of Hydraulic Burst Testing

1. Packaging Industry

Ensures bottles, cans, and flexible packaging can withstand internal pressures during filling, transportation, and storage.

Prevents leaks and ruptures in medical and food packaging.

2. Textile & Apparel Industry

Evaluates the burst resistance of fabrics used in sportswear, military gear, and industrial textiles.

Helps manufacturers improve material durability.

3. Automotive & Aerospace

Tests fuel tanks, hoses, and composite materials for pressure resistance.

Ensures safety in high-stress environments.

4. Medical Devices

Assesses the strength of IV bags, blood pouches, and implantable devices.

Guarantees reliability under physiological pressures.

Choosing the Right Hydraulic Bursting Strength Tester

When selecting a hydraulic bursting strength tester, consider:

Pressure Range – Should match the expected burst strength of the materials tested.

Sample Size Compatibility – Must accommodate different specimen dimensions.

Automation Features – Digital controls, data export, and compliance with industry standards.

Durability & Maintenance – Robust construction and easy servicing for long-term use.

Popular manufacturers include Mecmesin, Tinius Olsen, and UTS Test Systems, offering advanced hydraulic burst testers for various industries.

Conclusion

The Hydraulic Burst Test is an indispensable method for evaluating material strength and durability across multiple industries. By using a hydraulic bursting strength tester, manufacturers can ensure product reliability, compliance with safety standards, and improved quality control.

Whether in packaging, textiles, automotive, or medical applications, this testing method provides critical insights into material performance under pressure. Investing in a high-quality hydraulic bursting strength tester enhances testing accuracy, efficiency, and product safety—making it a crucial tool for modern industrial testing.

For more information on textile testing methods/standards

or textile testing machines, contact us:

What’s App: +86 180 2511 4082

Tel: +86 769 2329 4842

Fax: +86 769 2329 4860

Email: sales@tes.hk